Clearspan temporary structures can be used in any industry for any construction, warehousing or industrial needs; but as temperatures change, it’s important to understand the wind and snow load of these winter foundation coverings to ensure your inventory remains safe.

Your need for a temporary clear span fabric structure this time of year may vary from something personal such as a storage tent while you renovate your home to high-ranking tractor storage in the agricultural industry – or anything in between. These versatile structures offer the answer to many needs we face.

Like most things in life, however, temporary tent structures are not all created the same. So, while they are not only are they designed to meet your specific demands, the outdoor conditions where they will be constructed must also be taken into consideration. In the winter, wind and snow, for example, play a big role in determining specific requirements for your structure.

To make sure something lives up to its capabilities and promise, it needs to be created to do so. Let’s take a look at clearspan structures, winter foundation coverings and gain a better understanding of wind and snow load.

Snow Load

In general, snow load is the force on a building or structure’s roof caused by the weight of the snow (and ice) that has accumulated. Roofs are designed to hold a certain amount of weight before they can fail, increasing the risk that the entire roof and/or structure may potentially collapse. Depending on its design, this could be a lot – or a little – snow.

Code enforcement offices, either at the state or local level, set certain snow load requirements on buildings and structures that will be constructed. This is based on the average snowfall of the local area. It’s not often you see roofs collapsing in neighborhoods after recent snowfall – and these code requirements are why.

When it comes to tent structures, the same rules apply. The fabric must be able to hold the snow – or have a means of keeping its roof from collecting a large build-up of snow. Consider the standard A-frame style clear span tent – these have an 18° slope with the ability to hold a load of approximately 5lbs/square foot. In simpler terms, this is equivalent to about 3-4” of snowfall accumulation.

Tents of this stature are found throughout most of the United States, such as Florida, Georgia, Alabama, Texas, Tennessee, Kentucky, Oklahoma, as well as coastal areas in California, Oregon, and Washington state.

How Heating Helps Winter Foundation Coverings

If you are reading this article and scratching your head, wondering how you can invest in a large tent structure during the winter in Michigan, North Dakota, Colorado, and other areas with heavy snowfall, do not worry – you can still be covered, too. Literally!

All you need is a bit of heating under your winter foundation coverings.

Areas underneath the roof are naturally going to be warmer than outdoor temps. However, hours ahead of an anticipated heavy snowfall, raising the temperature in the structure is all that is needed to drastically increase the amount of melting snow you encounter.

To get technical, it takes about .51 BTU/lb to raise the temperature of space 1°. This heat combined with increased support at the legs, gable, and purlins will allow your building to have a snow load of approximately 40lbs/square foot. That is 8x’s more strength! With these engineered clearspan additions, a structure such as this will meet load requirements and building codes nearly everywhere.

More feasibly, areas that often see high levels of snowfall should consider a Tension Fabric Structure (TFS) as opposed to the standard A-frame we talked about above. The TFS option has a 36° continuous slope from the eve of the leg to the crown of the structure. How does this help? Well, the increased slope allows the accumulating snow to easily slide down the fabric of the roof. It is not the snow load that helps this tent and its durability, but rather snow shedding.

Wind Load

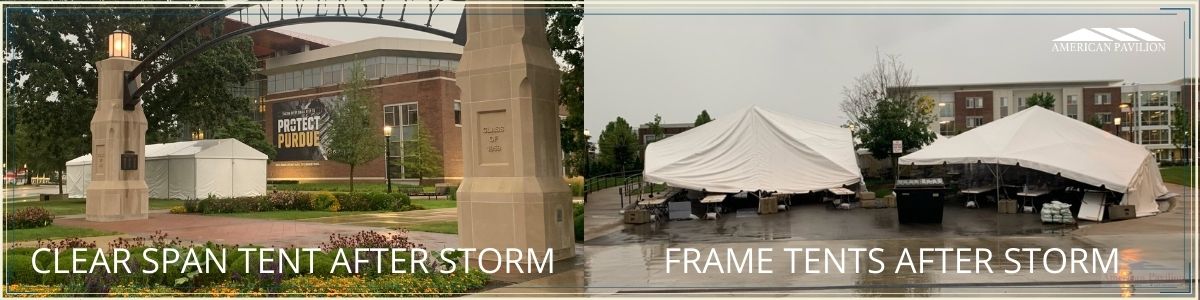

Wintertime brings snow, but it also brings wind. Lots and lots of wind. When you have a temporary tent structure, you need to make sure that it can withstand the winds it is left to face outside. As they were during the Derecho (inland hurricane) of 2020 that swept through Indiana and other midwestern states, tents picked up by wind can cause a lot of damage and a lot of loss.

Wind load is the pressure or force of wind upon a structure. And, like snow loads, there are often wind load codes and requirements in various states and locales to keep everyone – including the structure – safe. Wind loads are often based on average wind speed or known windstorms that frequent (or could frequent) the location.

To protect a temporary tent structure against the damage of winds, the following should be considered:

- Leg height of the structure

- Width of the structure

These are the two most important variables in determining the total wind speed rating. It is important to always investigate your building’s engineered wind load and compare it with what is required in the area it will be constructed.

The Foundation Surface

Although you have many options, it is suggested that you have a minimum of 5’ surrounding all concrete foundations. And, if you are pouring the foundation in the winter months, you will need to have a large covering – such as a larger clear span tent – to warm up the pour area and adjacent ground. This needs to be approximately 40-50° for a minimum of two to three days – and longer while it cures.

As each job will vary, you will want to ensure that the ground area maintains the proper temperatures and that heavy machinery can get under the tent to do the job (such as with a garage door). Creating your foundation during wintertime is possible. And just think – all the heat maintaining the temperature under the roof helps melt the snow. That is a win-win.

Considerations for a Concrete Winter Foundation Covering

- The size of the structure, plus additional area surrounding your foundation pour to allow enough internal heat to keep the correct temperature to surround the entire pour.

- Entry points for workers may include man doors as well as a large heavy duty garage door(s).

- When the pour is finished and cured, the removal will require heavy machinery to maneuver on top of the concrete to remove the structure. This may require the pad to cure for an additional week to handle the stress from the machines.

- Some companies prefer to get their initial plumbing and electrical set before removing the structure. In this instance, a crane will be required to remove the extruded aluminum frame.

These considerations are important to discuss during the planning phase to determine the potential costs and increased surface area adjacent to the pour. Depending on the start date, it may be beneficial to cover the ground before you begin excavation of the site; in this instance you may also want a garage door. Our team at American Pavilion can help you determine your exact site needs to ensure proper wind and snow load requirements for your winter foundation coverings.

All About Safety

At American Pavilion, we are all about safety. When you fulfill your needs with a heavy-duty fabric tent structure, you should be able to have the same confidence in the ability of the tent regardless of the season. Our engineered structures ensure that all wind and snow load requirements are met, keeping your structure and inventory safe year-round.

Whether you live in the freezing cold or along the windy coast, there is a temporary tent structure designed just for you.