EXCESS INVENTORY STORAGE

HOECKER TENT

DESCRIPTION OF PROJECT

- Additional storage space required for excess farm and agricultural supplies and inventory.

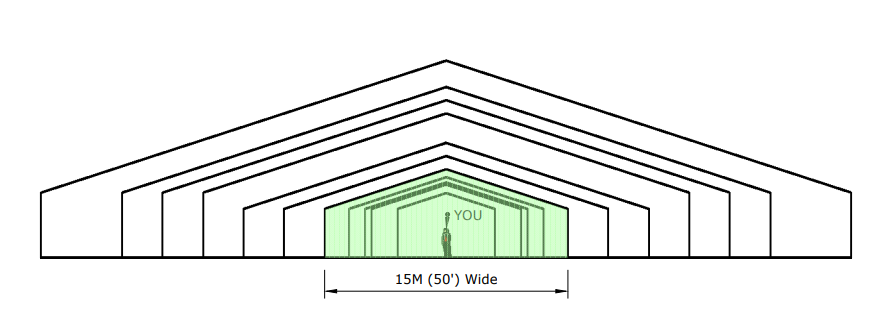

- Hoecker tent size was 15m x 55m x 3m.

- Structure was purchased but required to be moved and re-installed every 6 months to a new site.

- Inventory structure was built on a 200 year old concrete pad and required more time for drilling to be complete.

- Original drawing called for the tent to be flush against the loading dock ramp, but our installers ultimately decided American Pavilion could better meet their needs by moving the tent over a foot to create a flat landing for forklift clearance.

- Uses include: Inventory storage and warehouse space for excess supplies.

AT A GLANCE

| LOCATION: | Florence, South Carolina |

| RENTAL LENGTH: | Purchase (Structure moved from site to site every 6 months) |

| TYPE: | American Pavilion Excess Inventory Storage Series - Hoecker Structure |

| SIZE: | 15m x 55m x 3m |

| SQUARE FEET: | 9,000 sq-ft |

| ACCESSORIES: | LED lighting and one man door |

| SAFETY PACKAGE: | Yes (Emergency Exit Lights, Fire Extinguishers) |

| HVAC: | Originally no, but added to project later |

ADAPTING WITH AMERICAN PAVILION

To address the project engagement above, American Pavilion provided the Agricultural client with a 15m x 55m x 3m Hoecker structure. This was an extremely time sensitive project, as the client had a large shipment of inventory arriving in a few days. With half of their existing warehouse currently being renovated, they had no room left for storage of incoming inventory. It was imperative that our team understood the underground issues and additional required drilling time to install the clearspan Hoecker tent quickly. Our team erected the storage facility within 2 days - including all lighting attachments and sidewalls.

The client had an existing loading dock and the goal was to drive straight in and out of the tent and the initial drawing called for the tent to be installed directly alongside the loading dock ramp. Although American Pavilion had the capacity to meet these needs, our professional installation team advised that the structure be moved over a foot over to create a flat landing for the forklift clearance into the Hoecker tent which better met the needs of the client and improved logistics of the site.

During the installation process, the client requested their skilled team be involved in the fabric process, this way, when it came time to move the structure every 6 months, they would have the knowledge to remove the fabric themselves so just the frame remained. This ultimately saves the client money on each relocation while simplifying the moving process for our professional structure crew.

To fully optimize their experience, we utilized the following accessories with the inventory storage building:

PROJECT ENGAGEMENT

SAFETY PACKAGE

Our safety package includes emergency exit lights and fire extinguishers in case of an emergency.

TURNKEY INSTALLATION

This project was extremely time sensitive and required a turnkey solution to ensure the structure was erected within 2 days.

ADDITIONAL DRILLING

With many underground obstacles, our team needed significant more time for drilling during installation, while maintaining a 2 day turnaround time.

INVENTORY STORAGE

The structure was erected on 200 year old concrete pad and required additional drilling for the inventory storage.

LONG TERM VALUE

This structure provides long-term value as a purchase that has the capacity to be moved to a new location when required.

HVAC

Our HVAC systems create safer area to better meet requirements. This accessory was added on at a later time for this project.

MULTI-MOVE

This engagement requires relocation to a new site every 6 months. The American Pavilion team assists the client with each move.

LED LIGHTS

LED Lighting installation to ensure structure can be utilized at any time and help improve safety measures for the inventory storage.

SERVICE AREA

SOUTHEAST TERRITORY

For this South Carolina storage tent, the location fell into our Southeast territory which includes: Louisiana, Arkansas, Mississippi, Alabama, Georgia, Florida, South Carolina, North Carolina, Tennessee, Kentucky, Virginia & West Virginia.

Our nationwide team of installers can begin installation within one week* anywhere in the contiguous United States.

*Expedited 7-day project start is available on a case-by-case basis and is subject to available inventory. Typical project lead time is 30-60 days.

SERIES: EXCESS INVENTORY STORAGE

| SOLUTION: | At American Pavilion, we have a large variety of tent sizes and structure types. This client chose a 15m x 55m x 3m Hoecker tent - shown in green above. |