TEMPORARY MANUFACTURING FACILITY

LOSBERGER TENT

DESCRIPTION OF PROJECT

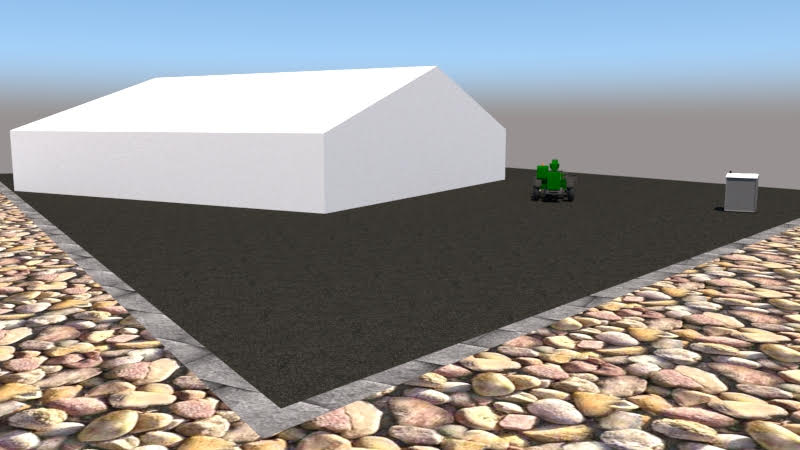

- A temporary manufacturing facility was needed to beta test new ways to recycle vegetation and maintain operational testing capacity before relocating to a permanent facility.

- The location required a variety of workers to work together to achieve the final solution.

- Losberger tent installation occurred while a paving team simultaneously poured asphalt for the roadway and pad outside of the tent.

- Entire process observed by inspector.

- Tent leg size needed to fit semi trucks, bulldozers and forklifts.

- Uses include: temporary manufacturing plant to test ways to recycle vegetation.

AT A GLANCE

| LOCATION: | Toledo, Oregon |

| RENTAL LENGTH: | 2 years |

| TYPE: | American Pavilion Manufacturing Series - Losberger Structure |

| SIZE: | 30m x 30m x 5m |

| SQUARE FEET: | 9,604 sq-ft |

| ACCESSORIES: | LED lighting |

| SAFETY PACKAGE: | Yes (Emergency Exit Lights, Fire Extinguishers) |

| HVAC: | Yes |

ADAPTING WITH AMERICAN PAVILION

To address the project engagement above, American Pavilion visited the location and erected the Losberger structure within 6 days: it took 1 day for the baseplate holes to be drilled and epoxied, 3 days for epoxy dry time, 1 day to build and raise the structure, and 1 day to add the top of the structure and the sidewalls. On the 7th day, the manufacturing client placed their generators and began bringing inventory and materials into the testing facility structure. The entire installation process was supervised by an inspector and followed strict safety protocol.

The structure required tall legs (5m high) to ensure semi trucks, bulldozers, and forklifts could enter and exit the structure.

This project was unique in that it required multiple teams of workers to collaborate simultaneously to ensure the project was completed within the time frame. Not only did the American Pavilion manufacturing series Losberger structure need to be erected, but a paving team was required to pour asphalt to create a pad outside of the structure, as well as to construct the roadway leading to the structure. Ensuring all necessary materials were in the location was crucial, as American Pavilion had to wait 8 hours for roadway asphalt to dry before driving on it - forgetting materials was not an option!

For the Losberger structure to be erected on the concrete pad, each hole needed to be drilled out and vacuumed to ensure no dust remained within the holes. Once the holes were drilled and cleaned out, the epoxy was applied, under the observance of an inspector, allowing for a 72 hour dry time based on weather conditions.

To fully optimize their experience and achieve maximum manufacturing and testing space, we utilized the following:

PROJECT ENGAGEMENT

LONG TERM RENTAL

The clear span manufacturing tent will be utilized for 2 years and must withstand the Oregon weather and safety requirements.

HVAC

Our HVAC systems create safer, temperature controlled areas to better withstand testing requirements.

LED LIGHTS

LED Lighting installation to ensure testing and manufacturing can be performed throughout all hours of the day.

SAFETY PACKAGE

Our safety package includes emergency exit lights and fire extinguishers in case of an emergency in the structure.

LEG HEIGHT REQUIREMENTS

The structure was erected on a mountain side and required large 5m high legs to ensure bulldozers, semi trucks and forklifts had access.

ASPHALT POURING

This installation site required asphalt pouring for a concrete pad and pathway leading to the location the structure was erected simultaneously.

SERVICE AREA

WESTERN TERRITORY

National Presence. Local Touch.

American Pavilion traveled to the West Coast for this clients installation. Our Western Regions include California, Oregon, Washington, Nevada, Idaho, Montana, Wyoming, Utah and Colorado.

For this project, once our team arrived in Oregon, it only took approximately 6 days to complete the installation. Our nationwide team of installers can begin installation in approximately one week*.

*Expedited 7-day project start is available on a case-by-case basis and subject to available inventory. Typical project lead time is 30-60 days.

SERIES: MANUFACTURING SERIES

| SOLUTION: | At American Pavilion, we have a large variety of tent sizes and structure types. This client chose a 30m x 30m x 5m Losberger tent. |